Unique Bargains 6542 High Speed Steel M2 Screw Metric Straight Flute Thread Tap And Twist Drill Set

$13.49 Original price was: $13.49.$9.44Current price is: $9.44.

- Unbeatable Quality, Unbeatable Value

- Get the Best for Less

- Friendly, efficient service, always online.

- Free Shipping Worldwide

Product Description

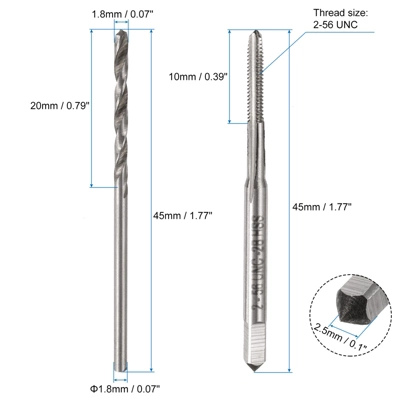

The thread tap adopts a straight flute design, with clear threads and no burrs. Screw tap provides downward chip removal, fast and precise tapping, suitable for through holes or shallow blind holes. Machine tap is used in drill presses, tapping, CNC, and milling machines. Not recommended for hand use and electric drill tapping. The twist drill bit adopts a spiral flute chip space design to remove chips quickly and cleanly. Cutting edges provide neat and smooth cuts. Use an appropriate lubricant (such as cutting fluid or oil) to reduce friction and heat build-up. 6542 (M2) high-speed steel tap & drill bit set offers excellent heat resistance and hardness for durability and longevity, and good cutting performance for clean, precise holes. Uncoated drill bit and tap sets are great for a wide range of applications. Tap and drill bit set is widely used for cast iron, aluminum, stainless steel, carbon steel, aluminum alloy, bronze, and hard plastics. Use with tapping oil to achieve higher-quality threads and more durable taps. The force must be uniform in tapping operations. Drill holes with a twist drill bit first, then tap with a thread tap. The tapping angle should be 90 degrees vertical and stable. The higher the hardness, the slower the speed. Fast speed with small torque; slow speed with high torque. The tapping depth should not exceed 1.5 times the diameter of the tap (for example, the diameter M5x0.8 is about 5mm, the depth should not exceed 7.5mm).

Product Highlights

- High-speed steel tap and drill bit set for durability

- Suitable for cast iron, aluminum, and stainless steel

- Straight flute design for clear threads and no burrs

- Twist drill bit with spiral flute for quick chip removal

- Titanium coating enhances hardness and reduces friction

| size | 2-56 unc + 1.8mm |

|---|

Be the first to review “Unique Bargains 6542 High Speed Steel M2 Screw Metric Straight Flute Thread Tap And Twist Drill Set” Cancel reply

Related products

Folding Tables & Chairs

Furniture

Unique Bargains Furniture Hotel Cupboard Sofa Bed Table Chair Cabinet Legs Silver Tone 8 Pcs

Reviews

There are no reviews yet.